HI-G Cuttings Dryer

HI-G Cuttings Dryer play a major role in separating the drilling fluids from drilled cuttings. So the HI-G cuttings dryer is considered as a core part of drilling waste management. In earlier time the use of TDU(Thermal Desorption Unit) was significant.

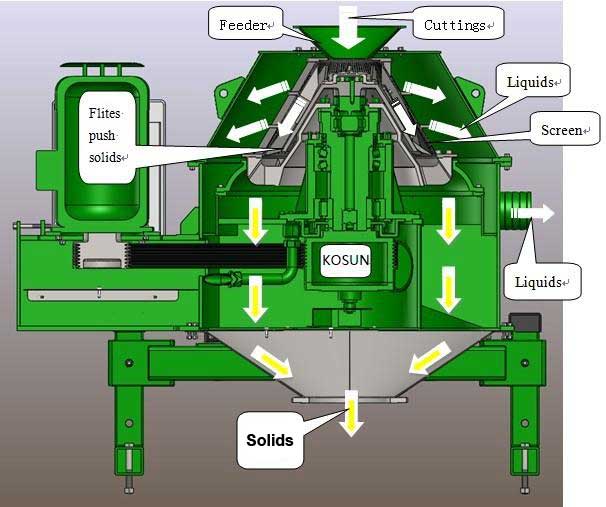

HI-G Cuttings Dryer have achieved lot of appreciation in drilling waste management. The vertical cutting dryer is commonly used to dry the dry the drilling solids . The working of a cutting dryer flows into two parts. One is transporting the solids and other is drying the solids.

HI-G Cuttings Dryer are the best option for the treatment of various waste streams such as oil sludge, drill cuttings and other organic waste material. The motors used in this procedure are non flammable. This will save your workplace from fire. The oil and water utilized in the process can be recycled for reuse. It is a heavy duty machine that leaves minimum footprints.

Whenever a successful drilling operation takes place the contamination of drilling cuttings with the drilling fluids occurs. This procedure is unavoidable. Separating the drilling fluid from the drilled cutting is really important as the drilling fluid is unrecoverable and economically unwanted.

It is a non incineration technology that is designed to separate hydrocarbons from the drilling oils and other fluids included in drilled cuttings. But today cutting dryers have taken its place due to following reasons.

It not only play a core role in drilling waste management but also enhances the performances of other equipment included in the procedure. The cutting dryer offer total fluid management. This will significantly reduce the impact of drilling activities on the environment.

HI-G Cuttings Dryer are quite light weight so can be used on any site. Making use of cutting dryer in the drilling waste management process will reduce the process time significantly.