In the field of drilling waste management, KOSUN has become a leader in the industry and has completely changed the industry with its many years of experience in drilling waste equipment abroad. By solving the technical shortcomings of traditional dryers, KOSUN has successfully developed cutting-edge solutions that provide efficient and effective drying operations to meet the needs of different drilling mud types. Today, we will talk about KOSUN’s breakthrough and demonstrate the successful implementation of its drying system equipment in the field of water-based mud.

Traditionally, cuttings dryers are mainly suitable for drying oil-based mud and synthetic mud cuttings. Unfortunately, they cannot meet the requirements of dry water-based mudstone cuttings. This results in frequent screen problems, often resulting in valuable drill cuttings being discarded. Furthermore, these limitations make these dryers unsuitable for use in water-based slurries.

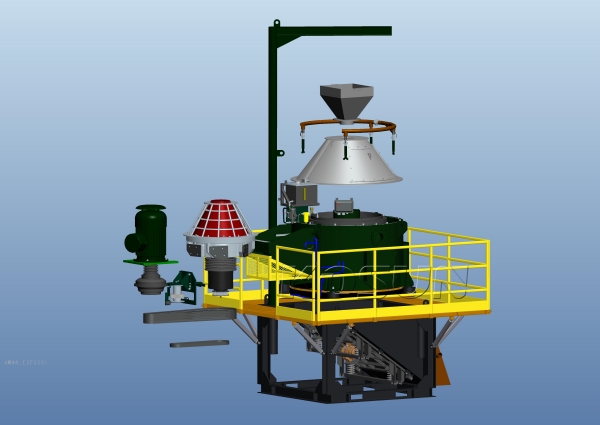

In order to solve the technical problems of traditional dryers, KOSUN embarked on an extensive research and development journey. The result of their efforts was a significant improvement in the performance of the cuttings dryer. KOSUN integrated the intelligent pulse injection control system into the dryer and successfully developed the second-generation cuttings dryer VC-2000 and the third-generation MINI dryer VC-800.

An important milestone in the development history of KOSUN cuttings dryer equipment is its successful application in the field of water-based mud. The second-generation cuttings dryer offered by KOSUN is equipped with an intelligent pulse jet control system and is proving to be a game changer. It effectively solves the technical problems faced by water-based mud drying, ensuring efficient operations and reducing waste.

KOSUN’s cuttings drying equipment can ensure that the solid phase moisture content of oil-based mud and synthetic mud reaches the ideal level after drying. For these types of mud, the moisture content is kept below 6%. For water-based mud, the moisture content after drying is between 5% and 8%. This optimized moisture content not only reduces waste but also enhances the overall drilling waste management process.

PetroChina’s Sulige Gas Field successfully implemented the KOSUN cuttings dryer equipment, which enabled cement slurry to be processed without landing on the ground, demonstrating the capabilities of the KOSUN cuttings dryer equipment. This milestone achievement demonstrates trust in Koseon’s advanced technology and highlights the reliability and efficiency of its drying system equipment.

KOSUN’s cuttings drying equipment has revolutionized the drilling waste management industry. By overcoming the limitations of traditional dryers, KOSUN has introduced cutting-edge solutions for different types of drilling muds. Through successful implementation in the water-based mud sector and optimized solids water content, KOSUN is leading the way toward a future of more sustainable and efficient drilling waste management. The impressive performance of PetroChina’s Sulige Gas Field further confirms KOSUN’s status as an industry leader.

Keywords: cuttings drying equipment, science and information, technical transformation, traditional dryer, water-based mud, oil-based mud, synthetic mud, cuttings drying, solid phase moisture content, PetroChina Sulige Gas Field