The cuttings dryer has a capacity of 40-50 tons per hour and usually handles cuttings with less than 3 percent oil content. It can be used for many types of drilling mud and is effective for cuttings drying in oil-based and composite mud.

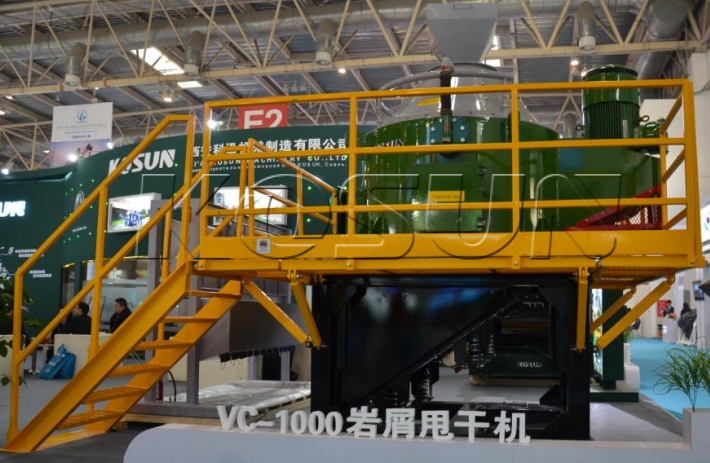

KOSUN Machinery is an ISO-certified manufacturer that can independently design and produce cuttings dryers. The vertical cuttings dryers dry the cuttings of oil-based and synthetic drilling mud by centrifugal force. The main rotating parts of the cuttings dryers are strictly tested for dynamic balance to reduce vibration and noise.

Vertical drilling cuttings dryer can be fully used for many types of drilling mud, mainly used for drilling cuttings drying oil and composite mud. Similar to other solid control equipment, such as drilling fluid vibrating screen, drilling fluid centrifuge, cyclone separator, vertical drilling chip dryer processing capacity also has a great relationship with mud viscosity. The viscosity of the mud is determined by a number of factors, including solid content, particle size, drilling fluid type and drilling fluid temperature.

Drying machine features:

1, the bearing selection of internationally well-known brand FAG bearings in the drying machine, with a speed of up to 900rpm, can form a 420G separation factor, effectively separating the liquid in the drilling cuttings.

2, the discharge scraper is made of high chromium cast iron, a long service life.

3, sieve basket selection of SS316L material, strong corrosion resistance.

4, independent oil circuit cooling system, effectively meets the needs of harsh environments.

KOSUN is a manufacturer of mud solid control equipment and solid control systems integrating product development, production, sales, and after-sales. The company focuses on the innovation research and development of drilling mud solid control equipment and drilling waste pulp treatment equipment and is committed to providing customers with excellent products. The company has a market share of products at home and abroad, and has formed a good reputation. Main application areas: oil/gas drilling, coal bed methane drilling, geothermal drilling, the horizontal directional crossing of trenchless urban construction, pipe jacking, shield, piling and other projects, drilling and mining waste treatment, river dredging, and so on.