With the promulgation of the new Environmental Law, the environmental requirements are getting higher and higher for oil fields, and free discharge of oil sludge will not be allowed any more. Oil Sludge Management is becoming a focal issue.

oil sludge management

Oil sludge is oil mixed with soil. They will be mixed together and become very difficult to deal with. Oil sludge is mainly from two aspects: Firstly, crude oil from the stratum to the ground and accumulated in all kinds of containers, large tanks and recycling pools and other ground facilities; secondly, oil sludge produced by oil well operations.

Oily sludge is mainly derived from oil field mining and sewage treatment plants. In general, the sludge oil content is from 10% to 50%, and moisture content is from 40% to 90%. The ultimate purpose of oil sludge management is to reduce the harmful resources. The common oil sludge treatment methods are solvent extraction, incineration, biological, coking, oily sludge profile control, and comprehensive utilization of oil sludge. The results show that the current methods for oil sludge management have their own characteristics and scopes of application. As the oil sludge composition is so complex, there is no treatment method that can treat all types of oily sludge.

According to statistics, the pollutant treatment market size is about CNY100~150 billion each year, and according to a rough calculation, the investment in oil sludge management plant needs more than CNY150 billion.

Since 2007, Daqing Oilfield have built nine oil sludge management stations, and the annual treatment capacity can reach 3.2 million tons, all the oil sludge had been treated harmlessly. Changqing Oilfield built a Longdong oil field sludge treatment station in 2013 and used the physically and chemically combined methods, the oil content of the treated oil sludge is less than 2%, and moisture content is less than 60%, while the crude oil can be recovered. Xinjiang Fengcheng Oilfield Work Zone uses microbial agents to deal with heavy oil sludge and sludge oil content is reduced from 15% down to below 2% after treatment, which is very good. The current test has been reviewed by the company.

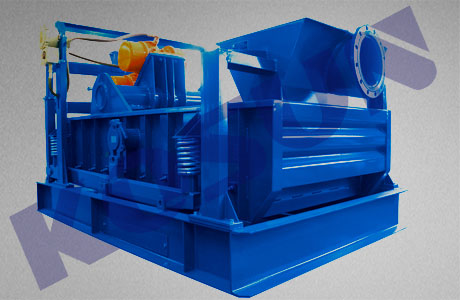

KOSUN can provide a corresponding set of oil sludge management plant, and our products have been exported to foreign countries, such as the United States, Europe, Russia, the Middle East and other regions, and our oil sludge treatment systems are well received by the foreign customers. If you need more information about our oil sludge management plant, please feel free to contact us! (Editor:Kosun Lily.Wang)

Kosun- China Solids Control Leader&Drilling Waste Management Expert

Tel.: +86 29 87304914

Email: sales2@adkosun.com

Contact person: Lily Wang

Online consulting: