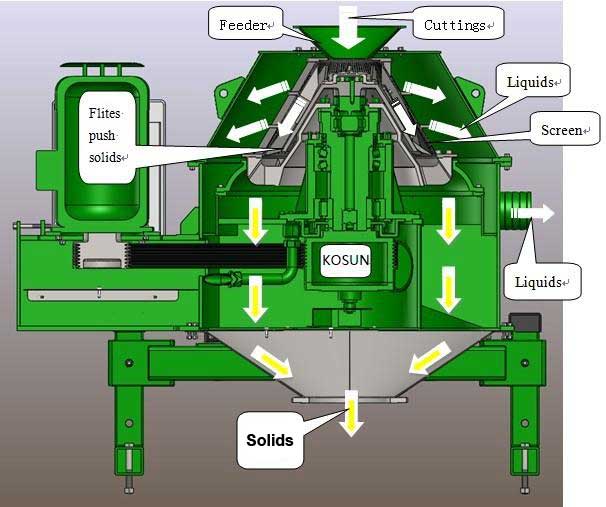

Vertical Cutting Dryer

Vertical Cutting Dryer of Kosun uses centrifugal force to dry synthetic base fluids or drilled solids in oil .

The population growth along with it a faster urbanization with 13 billion people today and multiplying at a terrifying rate, mean even faster increases of energy and resources consumption.

Energy has much to do with this as we consume more and as the atmosphere and oceans absorb more. As 80% of the world’s resources are consumed by 20% of its population. If ‘one’ is the amount of energy the average person in India or China uses per day then 400 is the number for a European. And more than 1200 for a North American.

There are number of energy resources to fulfill this excruciating demand of energy. The chief among them is – fossil fuel. There are few major exploration and production companies in this field – BP, Chevron and Statoil to name a few.

Drilling has been a well known method of reaching the reservoirs of fossil fuels beneath the vast ocean surface with the help of drilling rigs or on shore sites. The drilling rig itself comes in number of variations. The drilling process involves various stages namely – concession rights, seismic research, exploration drilling, appraisal drilling, concept development, development drilling, production, work-over/additional wells, and finally plug and abandon.

Drilling operations deploy a number of equipments to ensure safe and effective extraction of fuel. During the process, the cuttings dryer play an important role to recover the oil from drill cuttings.

It is known that large quantities of fluid are discarded with solid drilling waste management equipments. Vertical dryer ensures to separate good precious quantity of fluid from solid waste and restore the environmental balance before the discharge of drilling waste for further treatment, also making the process cost savvy for the investors.

So the key function of vertical cutting dryer could be traced as seperating the fluid from solid during the process of drilling waste management system and thereby preventing the loss of extracted oil mainly from large drilling cuttings and also make the seperated solid waste easier for further treatment to reduce the environmental damages once they are released back.